Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Manganese ore is an essential mineral in modern industry. Especially in the iron and steel industry, the amount of manganese ore used is as high as 90-95%. Since most manganese ores are fine-grained or micro-fine-grained, and there is a considerable amount of high phosphate ore, high iron ore, and symbiotic (associated) beneficial metals, it brings great difficulty to the beneficiation.

The common components in manganese ore beneficiation are manganese oxide and manganese carbonate.

There are 5 commonly used manganese ore beneficiation methods include ore washing, gravity separation, magnetic separation, flotation roasting.

Washing is a method of separating the ore and mud from the raw ore under the action of hydraulic, mechanical and self-friction, thereby improving the grade of the ore. The main factors affecting the washing effect are the physical properties of the mud, the type of ore, the strength of the mechanical force and the time.

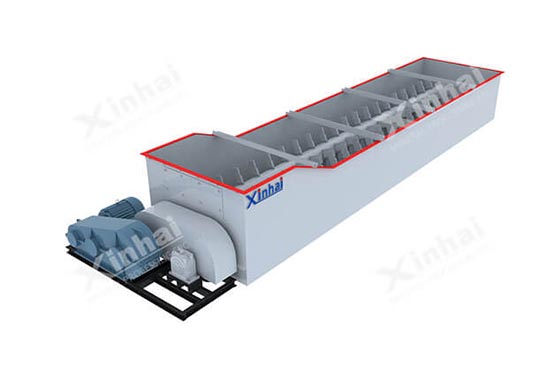

Manganese oxide ore is generally washed one or more times with a double spiral trough washing machine with strong scrubbing.

Most of the manganese carbonate ore should be washed, usually with the vibrating screen to spray water. The product on the sieve is washed ore, and the product under the sieve is returned and merged with the product on the sieve through spiral classification. Overflow is discarded or further recovered to get manganese minerals.

Commonly used ore washing equipment includes double spiral trough type ore washing machine, vibrating screen, cylinder washing screen, autogenous mill, etc.

Gravity separation is based on the density and particle size of various minerals for separation. The shape of mineral particles also affects the accuracy of separating by density to a certain extent.

Commonly used gravity separation equipment for manganese ore beneficiation includes jig, shaking table, and drum separator with heavy medium, cyclone, vortex cyclone, vibration chute and so on.

Jig is for processing coarse and medium-grained manganese ore, and shaking table is for processing fine-grained manganese ore.

Because the density of manganese oxide ore such as pyrolusite, pyrolusite, and brown manganese ore is about 4g/m³, which is significantly different from the density of silicate gangue, most of them can use gravity separation.

Manganese carbonate ore mostly adopts the combined process of dense medium and strong magnetic separation. The surrounding rock is discarded in the front section to restore the geological grade, and the later section is deeply beneficiated.

Magnetic separation is a method that uses the magnetic difference between minerals in a non-uniform magnetic field to separate different minerals. It is easy to operate, pollution-free, and low production cost. Strong magnetic separation has been applied to the beneficiation of weakly magnetic manganese ore for more than 20 years.

Manganese minerals are weakly magnetic minerals, and their specific magnetic susceptibility is quite different from gangue minerals. Therefore, the strong magnetic separation of manganese ore occupies an important position.

For manganese carbonate ore and manganese oxide ore with relatively simple composition and coarse grain size, using a single magnetic separation process can obtain a good separation indicator.

When separating manganese carbonate ore, the magnetic field strength of the magnetic separator needs to be above 480kA/m, while the magnetic field strength of the magnetic separator for separating manganese oxide ore is higher, generally above 960kA/m.

Flotation is based on the different physical and chemical properties of the mineral surface. In the highly dispersed and basically dissociated mineral suspension, under the action of the flotation reagent, one or a part of the minerals can be selectively adhered to the foam in the suspension and floated to the surface of liquid, while the other part of the minerals remains in the suspension. Then we scrap out the foam on the liquid surface to achieve the separation of the minerals.

Among the manganese minerals, rhodochrosite has better floatability, followed by pyrolusite and pyromanganese, and other manganese minerals, especially manganese soil, have the worst floatability. Therefore, flotation is only used for part of the fine-grained rhodochrosite and manganese oxide sludge.

The flotation of manganese ore can adopt positive flotation and reverse flotation. At present, anionic positive flotation is used at home and abroad, and cationic reverse flotation is still in the experimental stage.。

Since most of the manganese ore is carbonate and oxide minerals, the surface is easily wetted by water and has poor floatability. In addition, the flotation operation cost is high and the operation is difficult to control, so the flotation method is rarely used in industrial production.

The roasting of manganese carbonate ore mainly removes CO2 volatile matter and crystal water and turns it into manganese oxide, thereby improving the grade of manganese.

Manganese oxide ore mainly includes hard manganese ore, black manganese ore and brown manganese ore. Among these minerals, manganese generally exists in the form of MnO2, Mn3O4, Mn2O3, and other high-valent oxides. The impurity minerals are mainly Fe2O3, a high-valent iron oxide.

When the manganese oxide ore is reduced, the weakly magnetic Fe2O3 in the ore is reduced to the magnetic oxides Fe3O4, and γ-Fe2O3. The magnetic separator can be used to separate manganese and iron, which improves the manganese grade of the manganese ore.

At the same time, the high-valent manganese oxide in the ore is reduced to MnO, which creates conditions for the treatment of manganese oxide ore by acid leaching.

High-sulfur manganese ore is a metamorphic manganese sulfide-manganese carbonate ore. The purpose of roasting is to remove carbon dioxide and desulfurize.

The roasting of manganese carbonate ore is heating roasting, generally at 1000℃, and some up to 1150℃. The components in the ore generally do not melt or fuse, but only promote the decomposition of related components.

The above is the basic processing methods for manganese ore. In the actual production, you can refer this article to choose a basic process, but mineral processing test and technicians' advice are necessary too.

If you have any questions about this article or need more details, please contact our online customer service or leave a message below, we'll contact you as soon as possible.

1What Are the Processes and Equipment Used in the Manganese Processing?

0

0

340

340