Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Vat leaching refers to the percolation leaching carried out in the tank. It has the advantages of simple process, low investment and good recovery rate. Vat leaching is usually used for higher grade ores, and its leaching rate is generally lower than that of stirring tank leaching and higher than that of heap leaching.

In this paper, the relationship between gold leaching rate and ore particle size, ore mud content, charging method and aeration amount of gold in vat leaching process is studied in detail, which has certain guiding significance for industrial production of vat leaching process.

Let's drive in!

Select representative ore samples from a small gold mine. The gold deposit belongs to the primary poor sulfide gold deposit. The main metal minerals are pyrite (accounting for 3.83%), chalcopyrite (accounting for 0.035%), galena (accounting for 0.043%), sphalerite (accounting for 0.043%). The gangue minerals are mainly quartz, followed by sericite, calcite, feldspar, chlorite, amphibole and chalcedony. The analysis results of the main elements of the samples are shown in Table below.

| Element | Au | Ag | Cu | Pb | Zn | Sb | S |

| Content(g/t) | 7.00 | 4.50 | 0.012 | 0.037 | 0.0063 | 0.0016 | 2.03 |

( Analysis of main elements in ore )

The distribution of gold minerals is uneven, and can be seen in pyrite and gangue. The shapes of gold minerals are granular, veinlet, breccia, etc., and are mainly produced in pyrite and gangue near pyrite. The intercalation relationship of gold minerals in gangue is shown in the figure below.

| Embedded type | Gold content (%) |

| Pyrite wrapped gold | 29.37 |

| Pyrite fissure gold | 27.53 |

| Gold between pyrite and gangue | 9.47 |

| Gold in gangue | 33.63 |

( Gold mineral interlocking type )

The particle size distribution of gold minerals is shown in the figure below

| Test conditions | Grinding fineness (-75um %) | Leaching grade (g/t) | Leaching rate (%) |

| desliming | -2mm | 4.54 | 35.17 |

| Not deslimed | -2mm | 4.88 | 30.24 |

| desliming | 36 | 2.70 | 61.48 |

| Not deslimed | 36 | 3.28 | 53.16 |

| desliming | 65 | 4.26 | 39.14 |

| Not deslimed | 65 | 4.72 | 32.59 |

( Desliming test results )

| Grinding fineness and desliming grade | Yield (%) | Gold grade (g/t) | Gold loss rate (%) |

| -2mm / -30um | 5.10 | 3.45 | 2.51 |

| 36% -75um / -30um | 13.90 | 2.85 | 5.66 |

| 54% -75um / -30um | 15.10 | 2.12 | 4.57 |

| 65% -75um / -15um | 2.73 | 1.11 | 0.43 |

( Gold loss in desliming operation with different grinding fineness )

The test was carried out in a plexiglass column with a false bottom and a porous inflatable device at the bottom of the column. The ore is extracted by intermittent vat leaching. At the same time, because the ore is intermittently saturated with air, the oxygen content in the solution increases, so the leaching rate of gold can be improved.

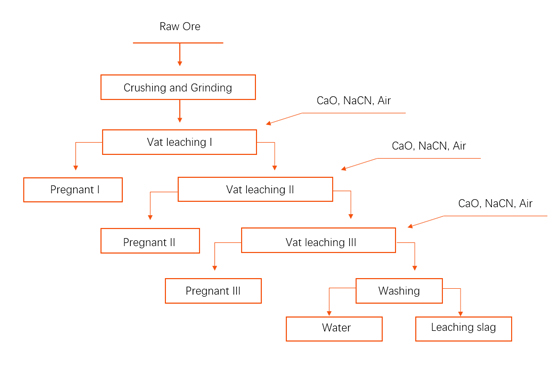

The experimental process flow chart is shown below.

( Vat leaching test process )

The fixing conditions are: the pH of the cyanide solution is 10-11.5, the sodium cyanide concentrations of the first, second and third batches of leaching solutions are 0.2%, 0.1%, 0.05%, respectively, the leaching time is 48h, 24h and 24h. After each pregnant solution is discharged, it is left to stand for 8 hours, and then new sodium cyanide solution is added.

According to the nature of the ore, the gold in this ore has a finer grain size and contains some pyrite-encapsulated gold. Therefore, it is necessary to conduct tank leaching tests of different grain sizes to investigate the effect of ore grain size on the gold leaching rate. The test indicators are shown in the table.

| Grinding fineness (-75um %) | Leaching grade (g/t) | Leaching rate (%) |

| -2mm | 4.95 | 29.29 |

| 36 | 3.34 | 52.29 |

| 45 | 4.40 | 37.14 |

| 54 | 4.51 | 35.29 |

| 65 | 4.71 | 32.71 |

( Ore particle size test results )

It can be seen from the table that the grinding fineness has a great influence on the gold leaching rate. When the fineness is -75um and the content of 36%, the gold leaching rate is the highest, and when the grinding fineness is increased, the gold leaching rate decreases.

The reason is that because the particle size of the ore is too fine, the powder ore and mud will block the liquid flow channel of the ore pile, which will affect the permeability of the ore pile, thereby affecting the contact dissolution and diffusion of the cyanide solution and the gold. Therefore, in the leaching process, the ore particle size should not be too fine.

The test conditions and results are shown in Table 1 and Table 2 shows the loss distribution of gold from slurries of -15um and -30um under different grinding fineness.

From the test results in Tables 1 and 2, it can be seen that before vat leaching, pre-deliming can significantly improve the leaching rate of gold, which is due to the increase in the permeability of the ore heap; the loss of gold in desliming is not much; the finer the grinding fineness , the effect of desliming on improving gold leaching is less obvious.

In the vat leaching process, there are two charging methods: wet charging and dry charging.

Dry charging is suitable for ore with a moisture content of less than 20%. Because there is a lot of air in the material layer of dry charging, it is beneficial to improve the leaching rate of gold.

Wet charging is that the ore sand is diluted with water first, and then pumped into the vat to build a pile, and the water is naturally filtered and then added with eco-friendly gold leaching reagent for leaching. Due to insufficient aeration in the material layer of wet charging, the dissolution rate of gold is reduced, which is not conducive to the recovery of gold. The test results of the charging method are shown in the following table.

| Charging method | Grinding fineness (-75um %) | Leaching grade (g/t) | Leaching rate (%) |

| wet method | -2mm | 4.95 | 29.29 |

| dry method | -2mm | 2.50 | 64.29 |

| dry method (desliming) | -2mm | 1.59 | 77.33 |

| wet method | 36 | 3.33 | 52.46 |

| dry method | 36 | 2.30 | 67.18 |

| dry method (desliming) | 36 | 1.43 | 79.61 |

| dry method (desliming) | 54 | 3.74 | 46.63 |

( Charging method test results )

The ore was crushed to -2mm, and then carry out the aeration condition test. The test results are shown in Table below.

| Inflation volume (L/(min*kg)) | Leaching grade (g/t) | Leaching rate (%) |

| 0 | 4.90 | 30.06 |

| 1 | 3.74 | 46.54 |

| 3 | 3.17 | 54.77 |

| 5 | 1.95 | 72.14 |

| 7 | 1.88 | 73.08 |

| 10 | 1.86 | 73.50 |

( Inflatable condition test results )

The test results show that aeration can significantly improve the leaching rate of gold. With the increase of the maximum amount, the leaching rate of gold increases accordingly.

When the maximum amount increases to 5L/(min*kg), the leaching rate of gold does not change much. Since the leaching rate of gold in the cyanidation vat leaching process depends on the concentration of cyanide and oxygen, under the condition that the leaching conditions are basically the same, proper aeration is beneficial to improve the leaching rate of gold.

(1) The ore particle size and mud content directly affect the leaching rate of gold, and desliming can improve the leaching rate of gold.

(2) The gold leaching rate of dry charging is 15% higher than that of wet charging, but pre-dehydration is required before charging, which complicates the operation.

(3) Proper aeration enhances the leaching of gold.

Through the above vat leaching test, it can be concluded that in industrial production, there are two options for the vat leaching process: one is the desliming and dry charging scheme, the test index is that the raw ore is crushed to -2mm, and the gold leaching rate is 77.33%. ; The second is the wet charging and aeration scheme, and the test index is that the raw ore is crushed to -2mm. The gold leaching rate is 72.14%.

If you also want to do gold beneficiation test or want to consult about vat leaching process, you can leave us a message here, we will contact you within 24h.

Last: 7 Tips for Energy Saving and Consumption Reduction in Mineral Processing Plant

1Summary of Gold Cyanidation Methods

996

996

10445

10445

2What Are The Gravity Separation Methods Used To Process Gold II?

3

3

5400

5400

What Are the Differences Between CIP and CIL?

11914

11914

0

0