Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

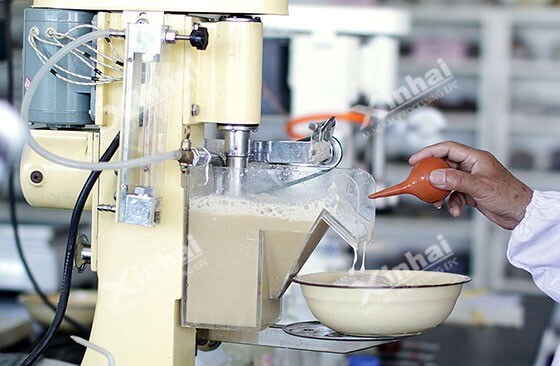

Froth flotation method refers to the beneficiation process of floating solid minerals from the suspension of water (slurry) according to the differences in the physical and chemical properties of the mineral surface.

There are many factors influencing the effect of froth flotation technology, including grinding fineness, pulp density, pulp acidity, reagent system, aeration and agitation, flotation time, water quality and slurry temperature. Here you'll learn more about the details and related solutions.

Let's dive in now!

Before the froth flotation process, the monomer needs to be dissociated and the particle size needs to be suitable. If the ore particles are too coarse, the useful minerals cannot be dissociated from the monomer. Even if the monomer dissociates from the mineral, it will be difficult to lift the bubble or fall off the bubble in the agitation process due to its large size and weight.

If the ore particles are too fine, it will lead to increase the cost of grinding operation, and produce mud easily. The slime has the characteristics of large specific surface area and strong surface activity, which is easy to absorb a large number of flotation agents or other mineral particles, thus resulting in the decrease of concentrate grade and recovery rate and the increase of flotation agent consumption. This is not conducive to the froth flotation process.

Therefore, the grinding fineness of the grinding mill must meet the following requirements before the froth flotation:

The useful minerals are liberated;

The granule degree of coarse monomer ore must be lower than the upper limit of particle size of mineral flotation (the vulcanized mineral is generally 0.25-0.3mm, the natural sulfur is 0.5-1mm);

Avoid mudding as much as possible.

When the particle size of ore particle size is less than 0.01mm, the flotation index will deteriorate significantly. It is suggested that suitable grinding fineness should be determined by ore dressing test and production practice data.

Pulp concentration is one of the main factors affecting the flotation index. The pulp concentration directly affects the recovery rate, concentrate quality, reagent consumption, production capacity and energy consumption of the flotation machine, flotation time and other aspects. Generally, the mineral with larger flotation specific gravity or coarser particle size should adopts higher pulp concentration, which is beneficial to improve the recovery rate, reduce the consumption of flotation reagent, and improve the productivity of flotation machine, but increase the flotation time. Low pulp concentration should be applied in the concentration operation, which is conducive to obtaining high-quality concentrate, but increasing the dosage of reagent, energy consumption and flotation machine required for processing each ton of ore, thus affecting the cost of ore processing.

Therefore, higher or lower pulp concentration has its advantages and disadvantages. It should be noted that the higher the pulp concentration is, the better the pulp concentration is. Too high pulp concentration will lead to the failure of free flow between the pulp and the bubble, destroying the aeration effect, and reducing the concentrate quality and recovery rate. In general, the appropriate pulp concentration should be determined according to ore properties and flotation conditions.

The acidity and alkalinity of the pulp are the main factors that affect the floatability of various flotation agents and minerals. The pH of pulp refers to the concentration of OH- and H+ in pulp,usually expressed by the pH value. For the neutral medium, the pH is generally equal to 7. For the acidic medium, the pH is less than 7. For the alkaline medium, the pH is greater than 7. The various minerals in the use of different flotation agent flotation will have a pH value between "floating" and"not floating", which is called the critical pH value. If most sulfide ores need to be floated in the alkaline or weak alkaline pulp, one is the acid pulp has a certain corrosion to the flotation machine, another is a lot of flotation agents, such as yellow, oleic acid, pine oil (no. 2 flotation oil) are usually effective in weak alkaline pulp. Under a certain flotation conditions,there exists a suitable pH value for any kind of mineral flotation. Only in this pH value, can the froth flotation process obtain the better index. Therefore,controlling the pH value of pulp is one of the important measures to control the effect of froth flotation process.

The flotation reagent system involves the reagent types,quantities, places and ways of dosing, which has a great influence on the index of froth flotation process.

If the dosage of reagent is insufficient,it will not reach the purpose of regulation, making it difficult to separate useful minerals. If the dosage of reagent is excessive, it will cause reaction,not only reducing the quality of concentrate, losing the selectivity, but also causing waste of reagent, increasing the cost of mineral processing. The dosing site should be added in one time or in stages according to the use and solubility of the agent and other factors. In the practice of mineral processing plant, most of them adopt the method of adding stage by stage to prevent overdose and invalidation and improve the efficacy.

For determining the type and quantity of agents, it is recommended to obtain accurate data through the ore dressing test to avoid affecting the froth flotation process. At the same time, in practice,the flotation machine operators should continue to summarize and analyze to get the appropriate dosing location and way.

The aeration is to send a certain amount of air into the pulp, then disperse into a large number of tiny bubbles, so that hydrophobic mineral particles adhere to the surface of the bubble. The smaller the bubble, the better the dispersion, the larger the total surface area of the bubble, which is conducive to the froth flotation process. However, if the bubble is too small and the rising speed will be slow. The purpose of agitation is to make the ore particles evenly suspended in the slurry in the tank and make the air diffuse and distribute evenly, resulting in a large number of"active bubbles". In general, aeration and agitation are conducted in the flotation machine at the same time, increasing the aeration and agitation appropriately can improve the flotation index, but too strong aeration and agitation can destroy the stability of the foam layer, causing bubbles mergers and a large amount of slime brought into the foam, thus dropping the concentrate quality,reducing the slurry volume of the flotation machine, increasing the power consumption and accelerating the wear of moving parts. So, the aeration and agitation must be appropriate.

Flotation time refers to the time required for separation of minerals when a certain recovery rate and concentrate grade are reached. The length of flotation time will directly affect the flotation index.In general, the flotation time is longer, the useful mineral recovery is higher,but the concentrate grade decreases correspondingly; the flotation time is shorter,the grade of tailings is higher. If the ore has good floatability, the grade of raw ore is low, the degree of monomer dissociation is high, the action of reagent is fast, and flotation time can be slightly short; On the contrary, the flotation time is long. In addition, the flotation time of ore with high mud content is longer than that of ore with low mud content.

The final range of flotation times required for various minerals must be determined by the mineral processing test.

The water used in the froth flotation process should not contain a large number of suspended particles, or the soluble substances and microorganisms that interact with minerals and flotation agents.Special attention should be paid when using the backwater, mine water and lake water.

The froth flotation process is generally carried out at room temperature, sometimes heating the pulp appropriately is conducive to obtain a good separation effect. Specific temperature should be determined according to the specific circumstance. If the factory conditions allow, it is best to use waste heat and waste gas as far as possible.

Conclusion

At present, the content of useful components in ore is lower and lower, the size of leaching is finer and finer,and the components are more and more complex, which put forward higher requirements for the froth flotation process. According to the above seven factors, the mineral processing plant must carry out the corresponding dressing experiment to guide the froth flotation process. The flotation machine operators also need to strengthen the technical level at the same time, timely identify problems appeared in the froth flotation process and take the corresponding measures to ensure that the ideal flotation efficiency.

If you have any question about flotation, welcome to contact us by live chat or leaving a message.

Last: 4 Factors Influence the Effect of Heap Leaching Method

Next: Difficulties and Solutions in Micro-fine Gold Extraction?

What Are the Differences Between CIP and CIL?

11954

11954

0

0