Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Froth flotation process as a complex physical and chemical beneficiation process, flotation stage has a great impact on the phosphate beneficiation index, and the effect of this stage will directly affect the subsequent processes. In order to ensure that phosphate ore flotation get a higher process index, the key to obtain a better technical and economic index of mineral processing is the main influencing factors of phosphate froth flotation.

Generally speaking, the phosphate froth flotation index will be affected by various factors, including grinding fineness, pulp concentration, flotation time, acid type and dosage, etc. In addition, the dynamics of the flotation foam layer, inflatable volume of flotation cell, and the water quality also have effect on the phosphate froth flotation. In this article, we will elaborate on these influencing factors one by one.

Let's start now!

Grinding is an important part of flotation plant. The flotation process index depends on the monomer dissociation degree of ore during grinding largely. In order to obtain better phosphate froth flotation index, not only should the minerals meet the requirements of monomer dissociation, but also the particle size of the useful mineral monomers should be as uniform as possible. However, due to various limitations in production practice, it is difficult to achieve complete monomer dissociation of useful mineral particles and gangue mineral particles in ores. Therefore, it is required to basically achieve the dissociation of the monomer, and reduce the connective organisms and over-grind as much as possible.

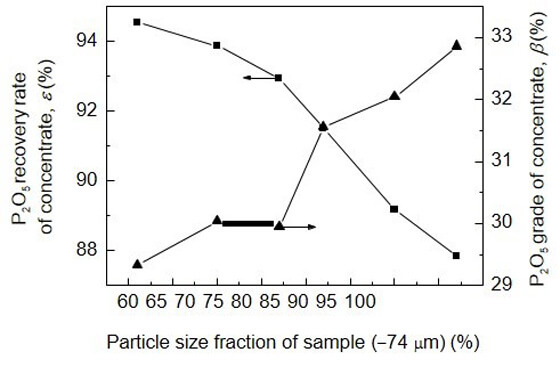

Taking the flotation test of a phosphate mine in China as an example, the relationship between the grinding fineness of phosphate ore and the recovery rate and grade of phosphate concentrate P2O5 , as shown in the figure. As the fineness of phosphate rock grinding increases, the grade of phosphate concentrate will increase; however, as the grinding fineness becomes finer, it is likely to occur the slime phenomenon, and the slime will affect the recovery of phosphate minerals. Thereby reducing the recovery rate. In the experiment, when the grinding fineness was −74 µm, which accounted for 82%, the recovery rate of phosphate concentrate P2O5 reached 90%, and the P2O5 grade could be increased to more than 32%. Continue to increase the grinding fineness, the concentrate P2O5 grade still increased, but increasing the grinding fineness not only increases the cost, but also easily makes the pulp slime, which is not good for phosphate froth flotation. Therefore, on the premise of ensuring the quality of the phosphate concentrate, the grinding fineness can be appropriately reduced.

Fig.1 Effect of particle size fraction of sample on P2O5 grade and recovery rate of concentrate

The pulp concentration mainly depends on the thickness of phosphate ore particle size, the concentration can be slightly lower when the particle size is fine, and the concentration should be higher when the particle size is coarse. To increase the feed concentration as much as possible in the case of ensuring that the grinding fineness requirements meet the standards, which is conducive to shortening the flotation time, saving reagents, and obtaining better phosphorus concentration process index.

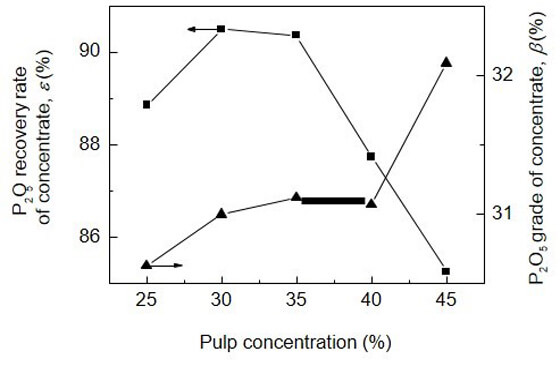

The relationship between the pulp concentration and the concentrate P2O5 grade and recovery rate, as shown in Figure 2. In the froth flotation process, the recovery rate of concentrate P2O5 is low when the pulp concentration is very low, but the grade is high. As the pulp concentration gradually increases, the recovery rate and grade increase. When the pulp concentration increases to 35%, the recovery rate reaches the maximum, and the concentration increases again, the grade increases slightly, but the recovery rate decreases instead. This is because the thicker pulp is advantageous during the flotation process, but if the pulp concentration is too large, the ore particles and bubbles cannot flow freely, and the aeration effect is deteriorated, which will reduce the recovery rate and concentrate grade and increase the flotation time. Therefore, the appropriate slurry concentration is about 35%.

Fig.2 Effect of pulp concentration on P2O5 grade and recovery rate of concentrate

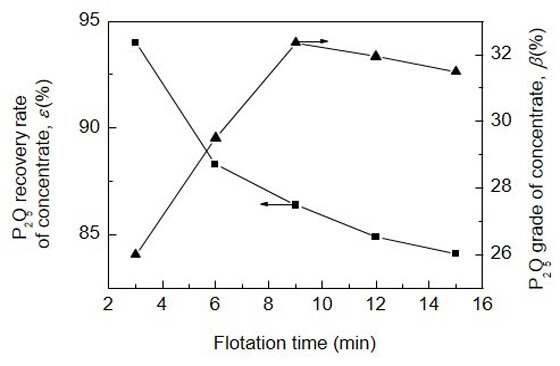

Flotation time is also an important factor affecting the phosphate froth flotation index. Other conditions being the same, the flotation effect is determined by the flotation time. The relationship between recovery rate and grade of phosphate concentrate P2O5 and flotation time is shown in Figure 3. In the initial stage, the flotation bubble volume is sufficient, the flotation speed is very fast, and the gangue minerals are quickly floated out, resulting in the recovery rate of phosphate concentrate P2O5 and the range of P2O5 grade change is large; but as the flotation time increases, the amount of bubbles decreases, the flotation process tends to balance, and the P2O5 recovery rate and grade change of the concentrate gradually tends to be gentle. Therefore, the appropriate flotation time is about 9 min, P2O5 recovery rate and grade of phosphate concentrate have reached good index.

Fig.3 Effect of flotation time on P2O5 grade and recovery rate of concentrate

Phosphoric acid and sulfuric acid are common inorganic acid inhibitors in phosphate flotation reagents. In the flotation process, adding different dosage of reagents will have a great impact on the phosphate froth flotation effect.

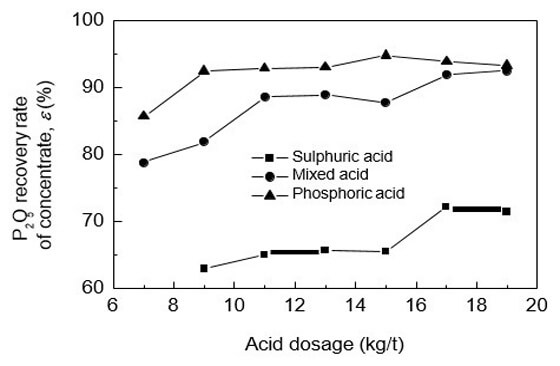

The relationship between the dosage of acid and the P2O5 grade and recovery of phosphate concentrate is shown in Figure 4. Under the condition of other flotation conditions identified, industrial sulfuric acid dosage increased to 19 kg from 9 kg/t, the recovery rate of concentrate P2O5 is lower, moreover, P2O5 grade hardly improved compared with raw ore grade, and the flotation effect was not ideal. While industry mixed acid and phosphoric acid as inhibitors of flotation effect is significantly higher than the industry sulfuric acid, and the flotation effect was the best when phosphoric acid was used as inhibitors, with the increase of dosage of phosphoric acid, phosphorus P2O5 grade of concentrate and recovery rate increase gradually.

Fig.4 Effect of acid dosage on P2O5 grade and recovery rate of concentrate

The dynamic balanced flotation foam layer is the main indicator of the normal phosphate flotation process, but also the basis of production operations. The normal and stable foam layer is characterized by appropriate bubble size and color, high degree of mineralization, crisp and non-sticky, more uniform, dense and good mobility and continuity. The amount of foam scraping is balanced with the speed of foaming. The foam layer has a certain thickness to prevent scraping of phosphate ore pulp. The thickness of the foam layer in each roughing tank is sequentially reduced, and the amount of foam is reduced from large to small. scavenging foam layer is thin and foam is slightly larger. Concentration operation foam layer is thick.

The aeration of the flotation cell should be adjusted according to the dynamic situation of the flotation foam layer. If the aeration capacity is too high, it will cause too much foam and the loss of coarse phosphorous. However, if the aeration capacity is too small, the amount of ore in the foam zone is too small, the coarse phosphorous can lose as well.

The water quality used for flotation has great influence on the flotation index of phosphate ore. Tailings water is generally recycled for flotation process, because the circulating water can reduce flotation reagent consumption. However, if the sludge content of the circulating water is relatively large, on the one hand, the sludge will reduce the floatability of the useful phosphorus minerals; on the other hand, the surface activity of the sludge is very strong, so the surface of the sludge will selectively adsorb a large amount of flotation reagents, resulting in reagents consumption, which is not conducive to the flotation process. Therefore, it is necessary to prevent unqualified recycled water from entering the phosphate froth flotation during the production process.

The above are the main factors affecting the phosphate froth flotation. At the beginning of the construction of the beneficiation plant, it is recommended that mine owners consult a manufacturer who can independently produce mineral processing equipment and has the qualification of the beneficiation plant design to formulate a scientific and reasonable flotation process to avoid unnecessary economic losses. In actual production, the operation state of phosphate ore dressing plant in the flotation stage can be effectively judged by combining the above influencing factors. For the operators of the flotation stage, they should understand how to judge the flotation effect by combining different factors that affect the flotation. Through the investigation of abnormal index, find out the factors that affect the index, so that the smooth operation of the mineral processing plant is guaranteed.

17 Factors Affecting Phosphate Froth Flotation

0

0

3813

3813

2Beneficiation of Phosphate Ore

20

20

3913

3913

What Are the Differences Between CIP and CIL?

11992

11992

0

0