Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

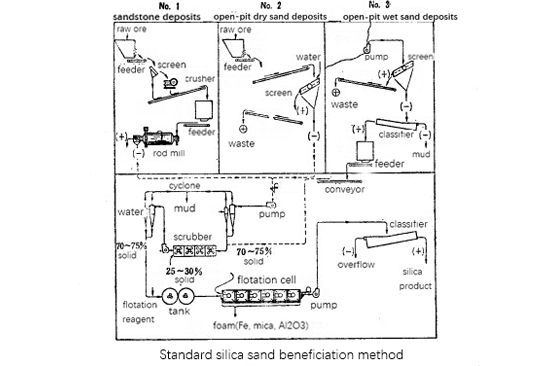

Silica sand is generally divided into three types: sand deposits, open-pit dry sand deposits and open-pit wet sand deposits. Although these three kinds of silica sand beneficiation methods have some differences, they are generally carried out in the following sequence of operations: pretreatment operations, classification and washing operations, flotation operations and concentrate processing operations. This article will introduce these four operations one by one to help you better understand the entire process flow of the silica sand washing plant.

The raw silica sand from the mining site must be crushed, screened, and ground before it can enter the subsequent process.

The operation of processing silica sand deposits is basically the same as processing hard rock. In a small silica sand washing plant, a jaw crusher is used to crush the raw ore to about 25mm. In large-scale silica sand washing plant, it is better to use two-stage crushing, and impact crusher is better than jaw crusher.

Then use a wet rod mill to grind the crushed silica sand to the particle size of the monomer separation, usually using an open-circuit grinding method, and only one-stage grinding is required. A spiral screen is installed at the discharge port of the ore mill, and the +0.83mm level material on the screen can be discarded or reprocessed.

When processing open-pit dry sand deposits, the dry silica sand is first transported to the washing plant by truck. After sufficient water is added, use a vibrating screen or an arc screen to screen. The upper sieve size (0.83mm) is further washed with a water jet, and then discarded or used for other purposes, while the lower sieve size is sent to the next operation.

When processing open-pit wet silica sand deposits, mud pumps are most suitable for hydraulic mining. The mined raw silica sand is sieved with a vibrating screen, the under-sieve size is fed to the dewatering classifier, and the sedimented sand is sent to the ore bin for storage.

Next, the pre-processed silica sand enters the classification and washing operations. In any case, a hydrocyclone or a classifier can be used in the primary classification of silica sand. In order to get rid of the surface pollution of the sedimentation of the classifier, silica sand can be treated in a scrubber. The scrubbed silica sand is diluted with water to 25-30% solids, and then sent to a secondary classified hydrocyclone by a slurry pump to remove the silica sand sludge generated during scrubbing.

In some cases, through the secondary classification, the Fe2O3 grade in silica sand can sometimes drop to the required standard. Therefore, sometimes a second scrubbing is necessary in silica sand washing plant.

Silica sand associated with mica, feldspar and heavy minerals containing Fe is first classified and washed in the plant, and then floated, which can usually reach the required grade.

The general flotation process is as follows: at the pulp concentration of 60-70% solids, adjust the pH to 3 with sulfuric acid, mix the slurry for 10 minutes, and then dilute to 15-25% solids, and then remove the biotite and titanium minerals contained in the silica sand. At this time, the collector used is 250-600g/t petroleum sulfonate and 500-1000g/t fuel oil.

If it is necessary to remove the feldspar impurities in the silica sand, add HF 1 kg/ton on the basis of the above process, after stirring, use amines as collectors, and perform flotation under the condition of pH 2-3 , and refined silica sand is recovered in the form of tailings. The obtained tailings are fed to a mechanical dewatering classifier to remove water to 15-20%.

The flotation machine is used to process highly corrosive silica sand under acidic conditions, so a specially designed acid-resistant structure (wooden trough, mold rubber, stainless steel, synthetic resin) is necessary.

The factory producing dry silica sand uses rotary desiccant containing gas fuel for drying. In addition, when the product needs to be pulverized to a particle size of -100 microns, it is dry pulverized using flint, gravel or porcelain grinding balls in a mill with silica sand or porcelain lining as the crushing medium.

Depending on the specific working conditions, sometimes a strong magnetic separator must be installed in front of or behind the mill to remove trace iron impurities that cannot be removed by wet scrubbing and flotation.

The above is an introduction to the four major processes of the silica sand washing plant, including silica sand pre-processing operations, classification and washing operations, flotation operations and concentrate processing operations. When choosing a process, you can first determine which of the 3 types of sandstone deposits, open-air dry sand deposits and open-air wet sand deposits your silica sand belongs to, and then select the corresponding process.

If you want to know more about the silica sand washing process and equipment, please leave a message or consult online customer service for more information.

What Are the Differences Between CIP and CIL?

12116

12116

0

0