Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Phosphate rock is an aggregate of phosphate minerals that can be used economically. Its mining methods are mainly divided into open-pit mining and underground mining. Because open-pit phosphate mining has some advantages of safe operation, good working conditions, unlimited working space, low mining cost and investment, among the total minerals in the world, there is about 80% of phosphate mines applying open-pit mining.

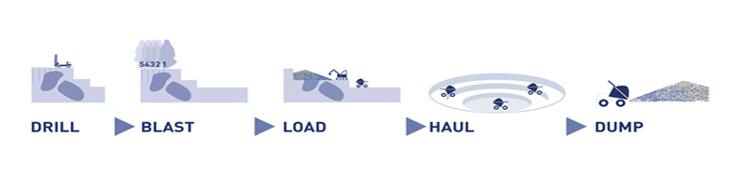

The open cast mining process determines the economic, technical, and environmental protection level of surface mining. This post will introduce the open-pit phosphate mining process.

The open-pit phosphate mining process mainly includes perforation and blasting, mining and loading, transportation, dumping and vegetation restoration. Based on the various topography and ore deposit cladding conditions, it is necessary to make the mining technology plan and choose the suitable mining process form, so that the open-pit phosphate mining can achieve the best economic effect.

Different mining processes contain different supporting equipment, involving mining, transportation and discharge. There are several types of mining processes widely used in open-pit phosphate mines in the world:

Blasting ---single bucket --- train process

Blasting ---single bucket --- automotive process

Blasting --- single bucket--- car --- belt conveyor process

Blasting --- skip craft process

Blasting --- ropeway process

Blasting ---single bucket --- car --- fixed crushing plant --- belt conveyor process

Blasting --- single bucket --- car --- semi-fixed crushing plant --- belt conveyor process

Blasting --- single bucket --- car-- -mobile crushing plant --- belt conveyor process

After the open-pit phosphate mine enters the deep recessed mining stage, its topographical conditions will be more complicated. Soft overburden, medium-hard roof rock formation, hard roof rock formation, different hardness ores, auxiliary personnel and machinery will all adopt various mining techniques.

According to the nature of the raw phosphate material, these open-pit mine production processes can be divided into intermittent mining processes, semi-continuous mining processes and continuous mining processes. Next, the advantages and disadvantages of each process system will be discussed one by one.

Intermittent mining process refers to a mining process which use cyclic equipment to form a discontinuous material flow in loading, transportation and discharge operations. Open-pit phosphate intermittent mining technology mainly includes:

Blasting --- single bucket --- train process

Blasting --- single bucket --- car process

Blasting --- cableway process

Blasting --- skip process

Intermittent mining technology has a strong ability to adapt to complex terrain. The process is flexible and changeable, with simple operation. Some large and medium-sized phosphate open pit mines will apply this technology system. This kind of process, especially the blasting --- single bucket --- car process and the improved blasting --- single bucke --- cableway (skip) --- automobile process, is widely used in some open-pit phosphate mines where the terrain is complex, the thickness of phosphate ore is not large and the frequency of spatial changes in dumps is high.

However, due to the disadvantages of low labor productivity, small capacity, high consumption and operating costs, low mechanization and automation, this intermittent mining process, especially the blasting --- cableway process, blasting --- skipper process, and blasting --- single bucket --- train process, just used for the small phosphate surface mines.

The semi-continuous mining process refers to a mining process in which some links are discontinuous and some links are continuous. The main feature of this kind of mining process is that the material flow in some operations is continuous, and the material flow in some operations is discontinuous. There are main mining processes:

Blasting-single bucket-car-belt conveyor process

Blasting --- single bucket --- car --- fixed crushing plant-belt conveyor process

Blasting---single bucket --- car --- semi-fixed crushing plant---belt conveyor process

Blasting --- single bucket --- car-mobile fixed crushing plant --- belt conveyor process

With the advantages of the high labor production, low consumption and operating costs, high degree of mechanization and automation, the semi-continuous mining process is suitable for large and super large open-pit phosphate mines. However, the semi-continuous mining process’ procedures is complex, workers are weak in operation. The semi-continuous mining process can’t adapt the complex terrain well.

Continuous mining process for open-pit phosphate mine, refers to the materials’ conveying of the loading, transportation and discharge is continuous. Continuous mining technology mainly includes:

Single bucket --- mobile crushing plant --- mobile belt conveyor process

Single bucket --- mobile crushing plant --- mobile aerial ropeway --- mobile belt conveyor process

Continuous mining technology has the advantages of high labor production, low consumption and operating costs, high degree of mechanization and automation. It is suitable for large-scale open-pit phosphate mining. However, continuous mining process has poor adaptability to complex terrain, especially in the case of frequent changes in the space of the stope and dumping site, the open-pit phosphate mining relocation’s cost is too high, so it is not popularized by small and medium phosphate mines.

With the rapid and continuous development of the mining industry, most open-pit phosphate mines apply two or more production processes for mining. This comprehensive production process, with its wide adaptability, ensures that each single mining process exerts its own advantages under suitable conditions.

The above is the introduction of the open-pit phosphate mining process. In order to improve the mining recovery rate and ensure the safe production, in actual mining, you need to fully explore the mine and select the appropriate mining technology by the mine geological report.

If you want to learn more about phosphate mining, welcome to leave a message or consult online customer service for detailed information. After phosphate mining process learning, you can click here know more about phosphate beneficiation.

14 Types of Excavators: Which One You Should Choose?

0

0

6190

6190

2Daily Maintenance of Excavator

0

0

2792

2792

32 Underground Gold Mining Method

0

0

4021

4021

What Are the Differences Between CIP and CIL?

11934

11934

0

0