Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

In this post, we are going to talk about spiral classifier.

Here is mainly introduce common types of spiral classifier used in mineral processing according to two aspects.

The height of overflow dam

The number of screw shift

Let's dive right in!

In mineral processing, the ores need to be grinded into a certain size that the fine-grained useful minerals and gangue minerals achieve full dissociation. And the over-grinding should be avoided at the same time in case that the sliming has the negative effect on the separation, which need the classifier to return the unqualified particles to the grinding mill for re-grinding, and separate the qualified particles in time.Therefore, classification takes an important part in grinding operation in the view of technology and economy aspect.

Now, the common classifiers in mineral processing plant are mainly mechanical classifier and hydrocyclone. Among them,mechanical classifier can be divided into spiral classifier, rake classifier,tank classifier and other types. With the development of classification operation, rake classifier is already replaced by spiral classifier, tank classifier is gradually replaced by hydrocyclone. Although the rapid development of hydrocyclone make the classifier lose its importance, but with the change of mineral processing requirement, people find that the spiral classifiers have their advantages.

According to the height of overflow dam (the relative position of spiral in tank and slurry surface), spiral classifier can be divided into high dam spiral classifier, low dam spiral classifier and submerged spiral classifier.

For the high dam spiral classifier, the position of overflow dam is usually higher than the bearing center of the lower end of the spiral shaft and lower than the upper edge of the spiral of the overflow end, so the settlement area of the high dam spiral classifier is larger than that of the low dam spiral classifier, and the height of dam can also be adjusted within a certain range, that is, the settlement area can be slightly changed according to the classification requirements, so as to adjust the classifying particle size.

The overflow dam of the low dam spiral classifier is usually lower than the bearing center of the overflow end, so its settlement area is too small and the overflow production capacity is too low, while the agitation effect of the spiral on the pulp surface is too large. Therefore,the low dam spiral classifier is only used to wash the sand ore with less mud or coarse particles, rarely used in the grinding and classification operation.

The overflow end of submerged spiral classifier is usually equipped with 4-5 spiral blades, all of which are immersed under the liquid level in the settling area, so the settling area of submerged spiral classifier is large and the classifying pool is deep.

Because the different structure between high dam spiral classifier and submerged spiral classifier, so they play different role in the classification operation. The high dam classifier is more suitable for the coarse particles (larger than 0.15mm), which is often used in the first stage grinding. The submerged spiral classifier is more suitable for the overflow products (less than 0.15mm) because of stable classifying surface, high overflow output and fine particle size, which is often used as combined unit by combining with the grinding mill in the second stage grinding.

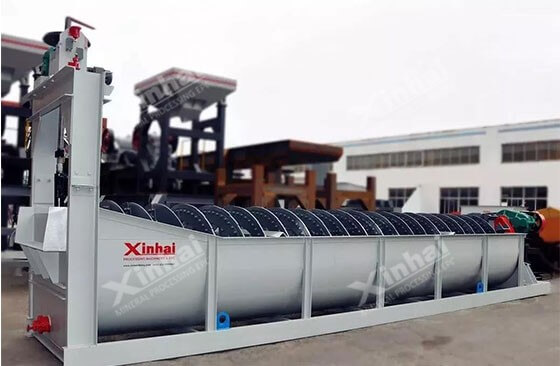

According to the number of screw shift, the spiral classifier can be divided into single spiral classifier and double spiral classifier. The classifying performance of the them is basically same,but the double spiral classifier is much better than the single spiral classifier at the return sand treatment capacity, overflow treatment capacity, screw diameter. Besides, the price of double spiral classifier is far higher than the single spiral classifier, which is more suitable for working with large grinding mill.

Mineral processing experts suggest that the single spiral classifier should be selected as far as possible under the determined processing capacity. According to statistics, the working load of the double spiral classifier is 0.6-0.75 times than that of the single spiral classifier, and the efficiency is relatively low. Therefore, the appropriate screw speed and number must be determined according to the processing capacity.

All types of classifiers mentioned above have their own advantages and have different effects on the classifier. According to the current different classifying requirements, different types of classifier have been optimized to achieve a good classifying effect. The mineral processing plant must clearly grasp the characteristics and working principle of each type of classifier, select it by considering the ideal process flow and production demand.

Last: What Are The 8 Factors That Affect Crusher Machine Productivity

14 Types of Hydrocyclone Used in the Mineral Processing

4379

4379

28 Technical Parameters of Hydrocyclone

53

53

4464

4464

35 Comparisons Teach You How to Choose Spiral Classifier or Hydrocyclone?

7

7

10715

10715

What Are the Differences Between CIP and CIL?

12100

12100

0

0