Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

The hydrocyclone is a high-efficiency classification equipment that separates two-phase fluids by centrifugation. And it is only composed of a cylinder, cone, feed body, overflow pipe, and underflow port. Due to the characteristics of simple structure, convenient operation, large production capacity, high classification efficiency, small footprint, no transmission parts and easy automatic control, hydrocyclone is widely used in many fields.

The role of hydrocyclone in beneficiation is mainly classification and concentration. This article mainly introduces the application of hydrocyclone in the classification and concentration process.

Since the classification efficiency of the hydrocyclone improved with the increase in particle size, the hydrocyclone can be used as a classification device to separate the feeding solid particles into coarse particles and fine particles.

As an efficient classification equipment, the hydrocyclone can replace the traditional spiral classifier and form a grinding system with ball mill in the closed circuit grinding process. It has high classification efficiency, large processing capacity, and large operating flexibility. In the open classification operation, the hydrocyclone can divide the particle groups of different particle sizes into two products. However, due to the distribution of flow during the classification process, some particles near the divided particle size (d50) have equal chances of entering the overflow and underflow. Part of the particles larger than d50 will enter the overflow which will cause the overflow having coarse particles. The part smaller than d50 will enter the underflow which will cause the underflow having fine particles. So the classification efficiency is reduced.

In the production process, if the slurry contains fine mud, it will have a significant impact on the operation of the equipment and the quality of the final product. Therefore, in the beneficiation of some ores, it is also an important process to desilt and wash the ore. For example, desilting before particle leaching can increase the extraction coefficient; desilting before particle filtration can reduce the specific resistance of filter cake and increase the filtration speed, etc.

The separation particle size is related to the diameter of the hydrocyclone. It is proportional to the square root of the diameter. That is to say, the smaller the diameter is, the smaller the separation particle size is. At present, the diameter of the smallest hydrocyclone in the world is 10mm. Ideally, its calculated separation particle size can reach 2 microns. Besides, the separation particle size is also related to the cone angle. The smaller the diameter is, the smaller cone angle is. So when hydrocyclone used for desilting, its diameter and cone angle are small.

Since the processing capacity of the hydrocyclone decreases as the diameter decreases, in practice, we install multiple hydrocyclones in parallel to meet the production requirements.

The purpose of concentration is to obtain a high concentration of underflow. When the hydrocyclone is used in concentration operations to process certain materials, its underflow volume concentration can reach 50%, and the underflow yield can reach more than 70%. The fine particles in the overflow enter the traditional concentrator for dehydration. Because the solid content is greatly reduced, we can decrease the diameter of the concentrator to reduce the amount of flocculant.

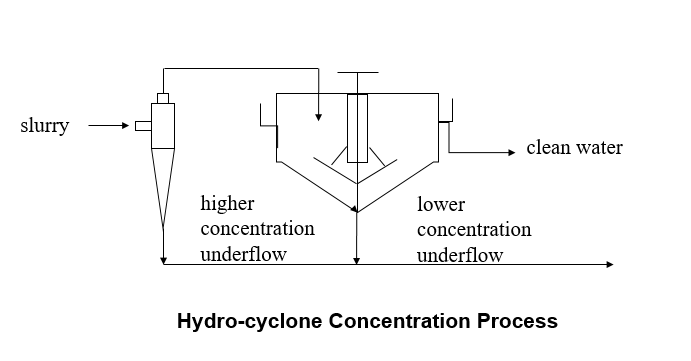

When the hydrocyclone is used as the concentration equipment, its typical use is to do pre-concentrate for the filter, screening equipment, dehydration centrifuge and concentration equipment, which can reduce the operating load of the filtration and dehydration equipment. And it significantly improves the processing capacity of the subsequent equipment. The process is shown below:

In short, the hydrocyclone is a sorting and concentration dual-use beneficiation equipment, with high classification efficiency. And its structure is simple. So it takes small footprint, and can also save costs to a certain extent. The specific use of the hydrocyclone and which process it is used for depends mainly on whether the demand of the mine owner is classification or concentration.

Last: 4 Common Barite Beneficiation Methods

Next: Matters Needing Attention in the Use of Vibrating Screen

1The Desliming of Hydrocyclone

2

2

4336

4336

2Development of Hydrocyclone

2

2

3900

3900

3Application of Hydrocyclone in the Classification and Concentration Process

1

1

3424

3424

What Are the Differences Between CIP and CIL?

11953

11953

0

0