Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

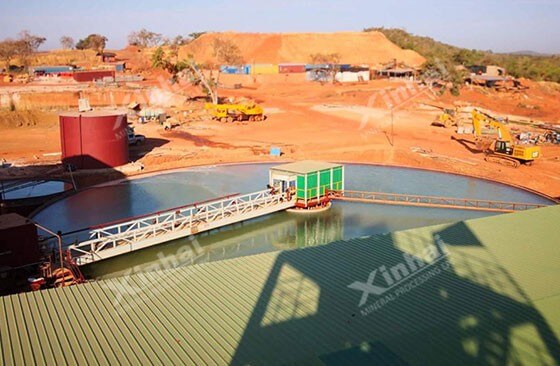

Thickener is a continuous enrichment and clarification equipment. It is mainly used for concentrate dehydration and tailings dehydration in wet dressing operation. At the same time can also be used for chemical, water, sewage and other solid slurry concentration and purification operations.

Thickener can be divided into ordinary thickener, tilted plate thickener and deep cone thickener. Among them, ordinary thickener is the common equipment in mineral processing plant. The biggest specific of ordinary thickener is simple structure and easy to operate. According to the transmission theory, ordinary thickener can be divided into peripheral transmission thickener and center driving thickener. In this article let's take a look at the similarities and differences between the two thickener.

Their structures are made of circular concentrator and harrow concentrator. the peripheral transmission thickener and center driving thickener harrow frame motion tracks are the same, both circular motion.The principle is gravity sedimentation, suspended in the slurry in the concentration pool under the action of gravity. The upper part is clarified water, directly from the concentration pool along the overflow, sink in the bottom of the solid particles with a rake concentrator continuously scrape it to the discharge port, so that the solid liquid separation.

In the concentrator, both kinds of concentrator equipment can be used for wet separation and concentration dewatering (the first stage of dewatering). It usually placed between concentrating and filtering. It also used as dewatering stage before concentrating sometimes.

Peripheral transmission thickener adopts steel bar cross frame to support the harrow frame. Combine the cross frame support and rake frame as one. The harrow frame has good rigidity and great intensity. However, the frame structure will be higher than the water surface in the working process, which will agitate the clarification area and affect the material settlement and overflow water quality.

The support of the center driving thickener adopts the support of the center shaft frame, which is hydrodynamic journal bearing. Bracket friction resistance is small, with efficient transmission torque, can effectively prevent overload caused by the rake arm and drive damage.

Thickeners are used for dewatering of concentration and tailings. But its use environment is not the same.

Peripheral drive concentrator is suitable for large processing capacity and high product concentration of large concentrator. While the center drive concentrator is suitable for small processing capacity, concentration does not exceed 0.3mm small plant.

Peripheral drive thickener is a more common large thickener equipment, the diameter is usually more than 50 meters, the largest can reach 100m.

Center drive thickener diameter is relatively small, generally within 24m diameter in the majority.

Cast iron funnel is installed around the ore discharge mouth of peripheral drive concentrator to improve the ore discharge efficiency. Center drive concentrator bottom of the pool is conical funnel, and the horizontal plane has a 6~10 degrees Angle, the bottom of the center of the pool opened a conical discharge mouth.

In addition to these differences, the two kinds of thickener specifications, mechanical composition are different, and two different models are still under the device class, such as peripheral transmission thickener is divided into peripheral rack thickener and surrounding the roller thickener, center drive thickener is divided into for hydraulic motor drive thickener and worm gear and worm drive thickener.

The above is the comparison between the two peripheral transmission thickener and center driving thickener. Special attention should be paid to choosing the appropriate thickener according to the actual plant selection. At the same time, it is recommended that all mine owners look for equipment manufacturers with overall qualifications to purchase concentrators.Obtaining a higher return on investment, while ensuring that the overall cost of the concentrator does not increase.

Last: What Are the Requirements for Ball Mill Testing, Start and Stop?

13 Commonly Used Dewatering Equipment for Beneficiation

0

0

3230

3230

2Introduction of Titled Plate Thickener?

0

0

3564

3564

3How to Conduct Right Maintenance for the Sludge Thickener?

6

6

5307

5307

What Are the Differences Between CIP and CIL?

12246

12246

0

0