Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

High-purity quartz raw materials refer to those natural quartz mineral resources whose SiO2 purity can be purified to 99.9% or above by the existing mature mineral processing technology. The purified high-purity quartz sand meets the strict requirements of modern high-tech industries.

In practical analytical tests, the chemical composition, dissemination size, gangue minerals, inclusions and lattice impurities are the main factors for the evaluation of high-purity quartz raw materials.

Let us understand one by one!

The chemical composition is the concentrated manifestation of the composition of the various elements in the quartz raw materials. The content of impurity elements in the raw ore has a key impact on the quality of the processed high-purity quartz sand, which determines the economic value and application fields of the product

The 12 trace elements that are harmful to the performance of high-purity quartz products are Al, B, Ca, Cr, Cu, Fe, K, Li, Mg, Mn, Na and Ni. Finding out the types and specific forms of occurrence of these harmful elements has important guiding significance for understanding the properties of raw materials and the process design of ore beneficiation.

There are obvious differences in the grain size characteristics of different types of quartz raw materials, which are closely related to the genesis of the ore deposit.

The particle size of veined quartz is mainly affected by the constraints of the mineralization environment and magmatic activity. There are often aluminosilicate minerals such as muscovite. The grain size of these minerals directly affects the dissociation degree of the monomer of quartz. When the particle size is smaller than the pulse width of the late quartz, the gangue minerals can be dissociated from the conjoined body.

The greater the intensity of the transformation of quartz by diagenesis and metamorphism, the more obvious the difference in the particle size of the patch with other minerals. At the same time, the type of conjoined body with muscovite and other gangue minerals has also changed from adjacent type to fractured and encapsulated type, which is not easy to dissociate.

Analysis of the mineral composition of the quartz raw materials can infer the formation process and method of the quartz ore, and select the appropriate beneficiation method according to the type of gangue minerals.

The chemical composition of independent minerals containing harmful impurity elements constitutes the vein minerals in quartz raw materials, especially some aluminosilicate minerals with high content of alkali metal elements and Al elements (such as white mica), which are the main carrier minerals of impurity elements. The type, content and particle size of these minerals have a serious impact on the quality of quartz raw materials.

Feldspar and mica are the most common vein minerals in quartz raw materials, while other vein minerals are related to the type of ore.

During the growth of quartz crystals, residual hydrothermal components or para mineral are easily mixed to form inclusions, and high-pressure metamorphism may also lead to the formation of sub-mineral inclusions(e.g. rutile)

Inclusions themselves can provide rich mineralization information such as symbiosis, temperature, and chemical composition of fluids. The distribution, phase state, homogeneous temperature and chemical composition of the inclusions are characteristics that can distinguish quartz of different genesis.

For high-purity quartz raw materials, the type and content of inclusions have a significant impact on the quality of high-purity quartz sand. On the one hand, they constitute the main source of impurity elements, and on the other hand, they will also change the melting behavior of industrial raw materials of quartz.

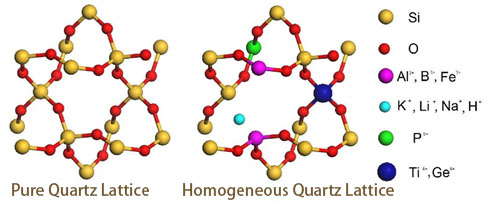

In addition to vein minerals and inclusions, a small number of impurity elements are present in quartz crystals in homogeneous form, constituting lattice impurities in quartz raw materials.

Schematic diagram of the structure of trace elements in a quartz lattice with a homogeneous structure

In the current processing of high-purity quartz minerals, lattice impurities can hardly be removed, and their content determines the limit of raw material purification potential.

The above are the five main factors for the evaluation of high-purity quartz raw materials. If you want to know more about your raw quartz ore, we can also provide you with ore tests. Now that we know the raw material standard of high-purity quartz sand, how to purify high-purity quartz sand from low-grade quartz? We will introduce to you the next article!

If you want to know more about high purity quartz, please leave a message to communicate with us, or consult our online customer service.

14 Steps of High Purity Quartz Sand Purification

0

0

5272

5272

What Are the Differences Between CIP and CIL?

12115

12115

0

0