Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

This post mainly introduces how to extract tin from tin oxide ore. Due to the high density of cassiterite (6.4~7.1g/cm3), gravity separation is often used to process cassiterite. However, cassiterite is easily sludged in the nature and in the process of ore sorting. Therefore, flotation is also used to recover fine-grained cassiterite from the fine mud and tailings.

Tin is one of the earliest metals discovered and used in human history. In recent years, new materials containing tin have developed rapidly. Titanium alloys containing tin can be used in aircraft engines. Tin and niobium compounds (Nb3Sn), as the important superconductor materials, are used for nuclear power generation. With the development of new technology, tin has been widely used, and the world's demand for tin is growing.

However, there is only 0.004% tin in the earth's crust, which is almost all in the form of cassiterite (tin oxide). Tin sulfide minerals are very few. Among 50 kinds of tin-bearing minerals known in nature, there exist about 20 kinds of main tin minerals. But the main source of economic satisfaction is cassiterite. It can be seen that the extraction of tin oxide is particularly important.

Tin oxide ore is mainly composed of vein tin ore and alluvial tin. The vein tin ore has high grade, coarse particle size and less mud content, which is easy to process; alluvial tin owns fine crystal particle size and more mud content, which is more difficult to process. And optional metal recovery rate is low.

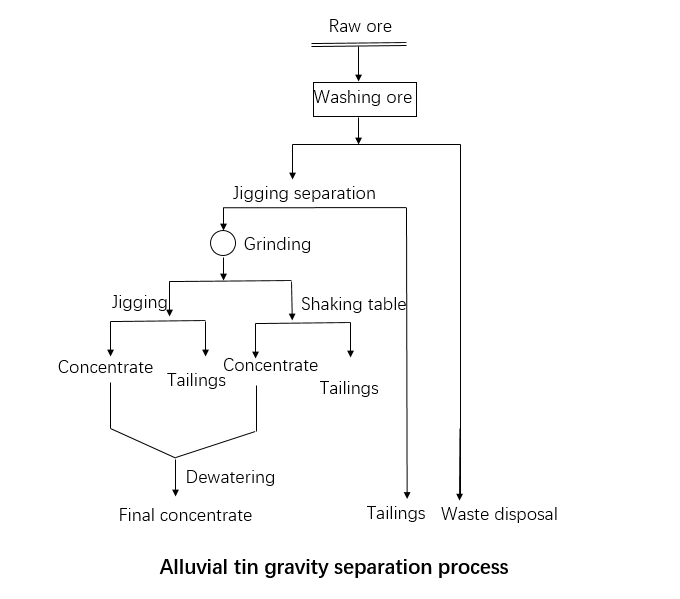

The method of beneficiation of alluvia tin is similar to alluvia gold. It is generally processed by gravity separation and gravity equipment. For the alluvia tin with high monomer dissociation degree, only gravity separation can be a better beneficiation index; monomer alluvia tin with low dissociation also needs to be ground by a rod mill to break the presence of contigs. The specific process is as follows:

1) Screening:

The raw ore is sent to the drum screen for sieving, the purpose of this step is to throw away the large waste rock.

2) Gravity separation roughing:

After screening, the remaining alluvia tin sent to the jig for initial sorting. This process aims to recover all alluvia tin minerals and improve the recovery rate of gravity separation. The coarse concentrate produced by the jig is sent to the mill, which is in order to destroy the existence of the tin mineral continuous structure in the concentrate, and achieve the maximum dissociation.

3) Gravity separation concentrate:

In order to improve the grade of concentrate, the products after grinding are sent to the jig for secondary process. The concentrate produced by the jig is the final product, and the tailings form jig need to be sent to the shaking table for recovering the fine-grained tin minerals. This operation can improve the recovery rate of the entire process. The concentrate produced by the shaking table and jigger will be sent to the concentrate pool and become the final product. The tailings are directly discarded.

4) Dewatering:

To obtain qualified concentrate products, the final concentrate need to do dehydration treatment with dehydration equipment.

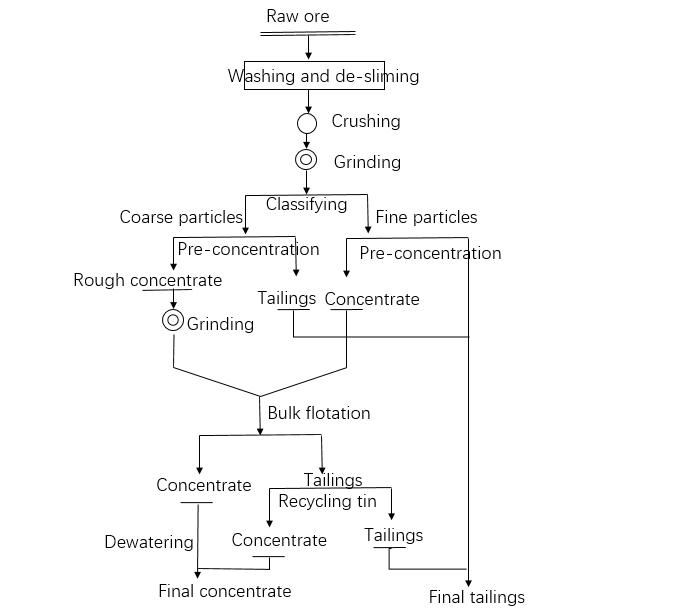

Vein tin ore varies from alluvia tin, it exists in the rock and forms a deposit or ore bed with associated metal or non-metallic minerals. The ore dressing process of vein tin ore is more complicated than that of alluvia tin, but it still uses gravity separation to treats the vein tin ore in actual production. In some special case, it also uses the flotation process to recover the cassiterite in the fine mud. The specific process includes grinding, washing, sorting and other operations.

1) Washing and desliming:

The raw ore is sent to the ore washing machine, and the sludge is treated with a classifier or hydrocyclone.

This step is an indispensable component for the treatment of the muddy tin oxide ore. Its main function is: after washing the ore, it can greatly reduce the amount of ore entering a section of grinding machine, and at the same time, it can also reduce the amount of particles that be over crushing. Generally, because of the reduction of the over-crushing rate of the one-stage grinder after washing and desliming, the recovery rate of the original ore can be increased by about 0.3 to 0.6%; the pre-desilting classification can greatly reduce the burden of the equipment and eliminate the Interference in the whole beneficiation process.

2) Crushing and screening:

After the demineralization, the raw ore is fed into the jaw crusher, crushed to about 10mm, and then sent to the grinding system for the next operation.

3) Grinding and classification:

The crushed material is sent to a rod mill for grinding to break the connection between tin ore and gangue; after that, the ground ore enters the spiral classifier for classification, which is divided into coarse and fine particles.

4) Gravity separation pre-concentration:

Fine-grained tin mineral bodies is sent to the shaking table. Because tin ore obtain a high degree of dissociation of fine-grained after classification and its output is low. A shaking table is required for recovery. The concentrate produced by shaking table enters the next operation, and the tailings are directly discarded.

The coarse-grained tin ore is sorted into jigs, which aims to recover all the tin bearing minerals and ensure the recovery- rate. And then the coarse concentrate produced by the jig enters the rod mill and grinds to maximize the dissociation of tin minerals.

5) Flotation:

The concentrate from the jig and shaking table is subjected to mixed flotation, and the concentrate first obtained still needs to be subjected to other metal separation flotation.

6) Gravity separation:

The tailings after flotation are sent to a shaking table to select qualified tin concentrate.

7) Dewatering:

The tin concentrate after the shaking table treatment also needs to enter dehydration equipment for dehydration treatment to obtain final products.

Tin exists almost in the form of cassiterite (tin oxide) in the earth's crust. Its density is relatively large, so gravity separation is most used for tin extraction. In the pre-dressing stage of tin oxide ore, the common equipments are trammel screen, cyclones, rod mills and other equipment. Common equipment for gravity separation includes jig and shaking table.

Drum screen is a screening equipment that specially developed for mineral processing. It can screen dry materials as well as slurry materials. It can not only process large quantities with high screening accuracy, but also not easily block the screen.

Hydrocyclone is a high-efficiency classification equipment that uses centrifugal separation of two-phase fluid. The role plays in beneficiation is mainly classification and concentration. Due to the different particle sizes and densities of fine slime and coarse sand, the centrifugal force they receive is also different, so the cyclone will play the role of desilting when it works, its structure is simple, the operation is convenient, the production capacity is large, and the classification efficiency is high.

The rod mill is a grinding machine with loaded steel rod. A wet-overflow type of rod mill generally used as a first-level open-end ore grinding. It is widely used in artificial sand and first-stage grinding of the beneficiation plants. Rod mill can save 40% power than general equipment, even discharging and high yield.

Jigging machine is a gravity separation equipment that separate light and heavy minerals by the different settling speed of minerals in vertical alternating water flow. Adopting conical slide valve reduces the failure rate by 80% and consumes less energy, which can process different materials according to its needs and improve the processing capacity by more than 35%.

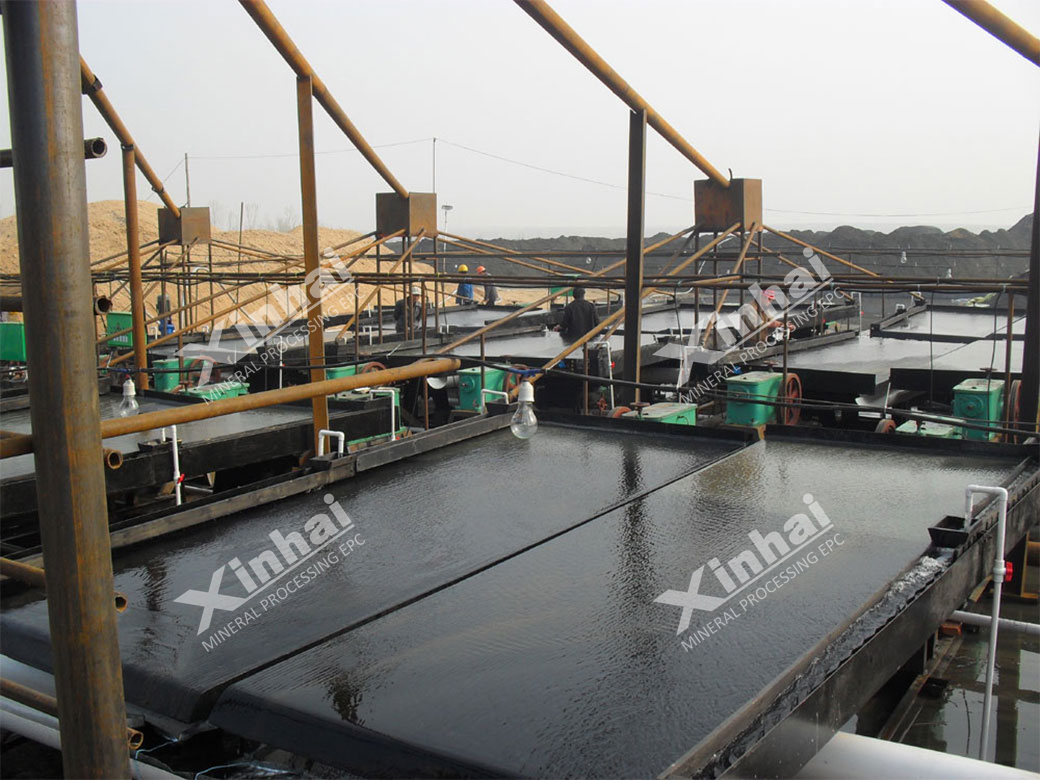

The shaking table is a gravity separation equipment that separates light and heavy minerals by the asymmetric reciprocating motion of the bed surface. Xinhai shaking table made a little improvement: it uses a cam lever bed head, changing the position of the sliding head on the rocker arm to adjust the stroke, and operating the smooth motor pulley to adjust the frequency of stroke.

How to extract tin from tin oxide ores more reasonably, economically and environmentally, the first thing should be conducted is to do a mineral processing test to comprehensively analyze the nature of the ore and determine which process methods should be used. And then comprehensively consider the actual conditions of the ore dressing plant, investment and other factors to determine the beneficiation plan.

Last: 4 Reasons and Solutions of Poor Gold Leaching Effect

Next: 3 Common Problems and Solutions in Ball Mill Operation

14 Ways to Teach You How to Improve the Index of Extraction of Tin Ore

6

6

4161

4161

What Are the Differences Between CIP and CIL?

12202

12202

0

0