Warm Tip: If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Placer gold mining methods are different for different burial conditions of alluvial gold deposit. According to the degree of mechanization, there are 5 types of placer gold mining methods: gold dredger mining method, hydraulic mining method, bulldozer mining method, semi-mechanized mining method and manual mining method. This article will briefly introduce the process flow, applicable conditions, features and the main equipment used in these 5 placer gold mining methods.

The dredger mining method of placer gold is to mine placer gold in the river by means of the dredger. Due to its simple operation, high work efficiency, and high benefit, the gold dredger is widely used.

Process flow: first use the digging bucket of the gold dredger to do placer gold mining, and feed the mined placer gold into the trommel screen for ore washing and screening, and then use the chute and jig machine for ore beneficiation, and finally use belt conveyor and chute to discharge it into the goaf.

(Placer gold mining process)

Applicable conditions: The gold dredger mining method is suitable for mining alluvial gold from river floodplain, shore, branch valley and their over-mining areas. When mining frozen placer gold mines, they should be thawed in time to prevent seasonal re-freezing.

Features: Dredger mining method has the advantages of large production capacity, continuous stability, and low cost, but the construction investment is relatively large.

Main equipment: The commonly used mining equipment in the dredger placer gold mining process is a gold dredger, bulldozer or excavator.

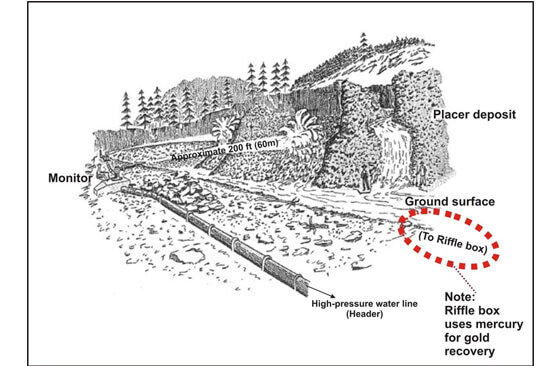

Hydraulic mining is an open-pit placer gold mining operation. It transports the solid-liquid mixed slurry formed by the water jet to the soil and rock to the beneficiation plant or dump under the action of hydraulic power.

Process flow: First, water guns are used to flush the placer gold, the slurry flows into the sand pump pond by itself, the sand pump lifts the slurry to the beneficiation equipment for beneficiation, and then the tailings are automatically discharged to the dump or goaf; Or use a bulldozer to strip the topsoil layer, and transport the gold-bearing ore to a sand pump pond or a hydraulic washing station, wash the ore with a water gun, and then use a sand pump or a hydraulic hoist to transport the slurry to the beneficiation equipment for beneficiation, and the tailings are automatically discharged to the mining empty area or waste dump.

(Hydraulic mining of a placer gold deposit)

Applicable conditions: The hydraulic mining method is suitable for the branch valley or terraced placer gold beds and over-mining areas where the ore body has a large slope and is easy to wash.

Features: The hydraulic mining method has the advantages of low investment and quicker results; however, it has high cost, high power consumption and material consumption.

Main equipment: In the hydraulic placer gold mining process, the mining equipment used in the first mining process is a water gun and sand pump, and the mining equipment used in the second mining process is a bulldozer, a water gun sand pump or a hydraulic hoist.

Bulldozer mining method is a process that uses bulldozers to complete open-pit mining of placer gold deposits. Bringing the level of placer gold mining technology into a new stage. Especially in some mining areas where water resources are insufficient and gold dredgers cannot be used, it is best to use bulldozers for placer gold mining.

Process flow: Bulldozers can be used to strip the topsoil, to excavate and supply ore, and then use chute to do washing, and make use of bulldozers (loaders or scrapers) to discharge the tail of the placer gold mining process ; It is also possible to use bulldozers and excavators for stripping, mining, automobile transportation, and the process of placer gold mining in the beneficiation of the washing and concentrating unit.

(Bulldozer mining method for placer gold deposit)

Applicable conditions: Bulldozer mining method is suitable for mining water-freezing placer gold ore with thick gold-bearing layer and placer gold ore with high clay content.

Features: It has the advantages of high bulldozer efficiency and good beneficiation effect. But the mining cost is higher.

Main equipment: In the bulldozer gold mining process, the equipment required for the first process is bulldozer, excavator (loader or scraper), and beneficiation chute. The equipment required for the second process is bulldozers, excavators, automobiles, and washing units.

Semi-mechanized mining method is a process that combines mechanical equipment such as bulldozers with manual mining.

Process flow: The semi-mechanized mining process is to first wash away the topsoil through an artificial waterway, then use a bulldozer to mine, and then use a chute for beneficiation; or use a bulldozer to strip and mine, and then use the chute to wash the ore; placer gold mining can also be carried out by manual ore supply and unit beneficiation method.

Applicable conditions: The semi-mechanized mining process is suitable for mining shallow and scattered small ore bodies; or for stepping back on scattered and scattered missing ship mining edge ore blocks.

Features: It has the advantages of low investment, quick results, flexibility and so on. But it is also easy to waste resources.

Main equipment: The equipment needed for this placer gold mining process are bulldozers, artificial water channels, chutes, and various small and portable washing units.

The manual mining process is a method that uses simple chute beneficiation, stripping, mining, ore supply and tail discharge.

Process flow: Basically, placer gold mining operations are completed through manual mining, ore supply, ore washing, tailing, and panning; or using artificial waterways, artificial water ditches or small shafts.

Applicable conditions: This process is suitable for mining scattered lost ore nuggets or unexplored placer gold ore.

Features: Manual mining method can provide information for geological exploration; but it is easy to damage the environment.

Main equipment: The equipment used in the manual mining process includes gold pans and large chutes.

Among the 5 placer gold mining methods, the most widely used is the dredger mining method. Because it has the advantages of large production capacity, continuous stability, and low cost, it can complete efficient mining operations in river channels, branch valleys and other places where placer gold is easily formed. The hydraulic mining method is more suitable for mining branch valleys or terraced placer gold mines with large slope and easy to wash. Bulldozer technology is more suitable for mining frozen placer gold ore and placer gold ore with high clay content. Semi-mechanical mining method and manual mining method are less used now because of their relatively low production capacity.

You can choose a suitable mining method according to the characteristics of the your placer gold deposit.

1Daily Maintenance of Excavator

0

0

2797

2797

What Are the Differences Between CIP and CIL?

11964

11964

0

0